HYDRAULIC C-FRAME PRESSES FOR MEDIUM AND HIGH PRODUCTION

We have designed the CF/VR series c-frame hydraulic presses with three different power ranges, from 80 to 150 tonnes.

Specifically designed to perform work involving deep-drawing, stamping, die-cutting, forming, etc. for medium and high volumes.

The latest generation CF/VR series hydraulic presses now feature a wide range of uses including the possibility of incorporating these machines in automatic production lines.

They operate with a hydraulic pressure lower than 290 bar to ensure the greater durability of the hydraulic system as a whole.

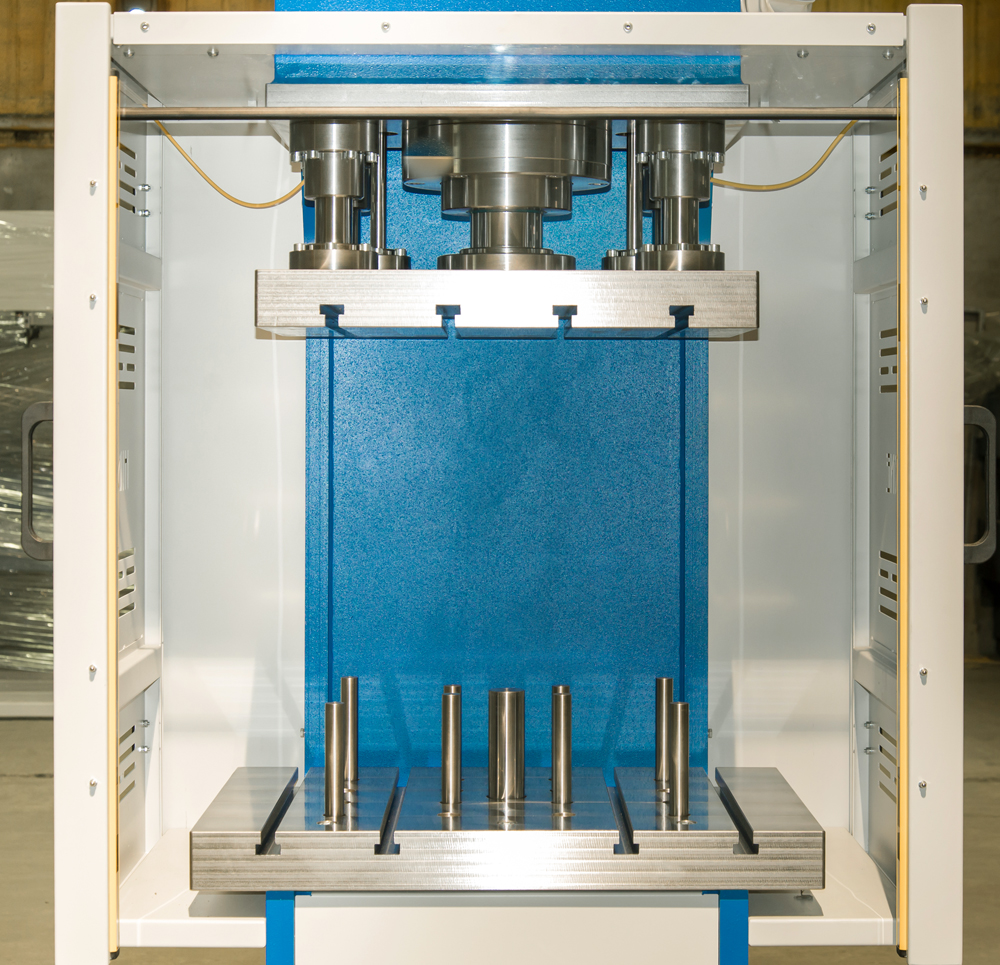

STRUCTURE AND TABLES

CF/VR-series c-frame presses consist of an electro welded structure made solely of S355JR steel. They are stabilised and machined at the end of the structural welding process to ensure perfect parallelism and precision. Calculated and designed by finite software. With all of this, we always guarantee our high precision and quality standards.

These models are equipped with a mechanized lower and upper CK45E steel table with DIN-650 grooves. The upper table ensures perfect alignment by means of four cylindrical lateral guides of 50 mm diameter with anti-friction bimetallic caps.

CYLINDER AND HYDRAULIC UNIT

The main cylinder is single-acting with a chrome plunger and maintenance-free anti wear guides.

For quick approaching and returning, 2 double-acting lateral cylinders with chrome plunger and non-wearing guides have been installed, which allows us a fast approaching and return speed. Incorporates two independent hydraulic safety blocks.

A motorized hydraulic unit with a pre-filing valve for approaching and returning and a fixed flow rate pump for working at constant speed..

It is equipped with a directional vale, a pressure relief valve, a decompressing valve and an air-oil cooling system.

They are supplied with a glycerin gauge with reading in tonnes.

ELECTRIC INSTALLATION AND SAFETY

Equipped with a Siemens SIMATIC S7 1200 PLC as standard, along with an adjustable panel featuring a 7ʹ touch screen model MPT-700. It allows for programming the power, cylinder stroke, and speeds. It has a storage capacity of 300 memories.

Electrical and hydraulic maneuvers are redundant and self-controlled. They incorporate an additional safety block and self-control devices for operation and safety. Includes verification and certification of correct operation and safety distance for photocells.

Operation is carried out using a low voltage electric pedal.

To ensure safety, it incorporates type 4 PLe safety light curtains, located in the front work area, two accessible side protections with polycarbonate windows, and interior LED lighting.

Supplied with an instruction manual.

Complies with all essential safety and health requirements according to CE regulations.

TECHNICAL FEATURES

| MODEL | CF-80/VR | CF-100/VR | CF-150/VR | |

|---|---|---|---|---|

| Power | t | 80 | 100 | 150 |

| Motor power | kw | 7.5 | 7.5 | 11 |

| Throat depth | mm | 340 | 375 | 400 |

| Working speed | mm/s | 5-9.7 | 5-9.7 | 5-7.3 |

| Approaching speed | mm/s | 162 | 162 | 148 |

| Return speed | mm/s | 230 | 230 | 215 |

| Maximum pressure | bar | 290 | 290 | 290 |

| Piston stroke | mm | 450 | 450 | 450 |

| Lower table | mm | 800×550 | 850×600 | 900×650 |

| Upper table | mm | 650×400 | 700×450 | 750×500 |

| Max. vertical light | mm | 650 | 650 | 650 |

| Working height | mm | 850 | 900 | 950 |

| Total front | mm | 1210 | 1240 | 1360 |

| Total lateral | mm | 1500 | 1950 | 2135 |

| Total height | mm | 2630 | 2790 | 2910 |

| Weight | kg | 2980 | 3820 | 5100 |

OPTIONAL ACCESSORIES

- 800 mm vertical light

- Robotics adaptations.

- Hydraulic connections for peripheral adaptations.

- Hydraulic cushion.

- Hydraulic ejector.

- Geometry adapted to your needs.

- Industry 4.0

- Router for remote access.