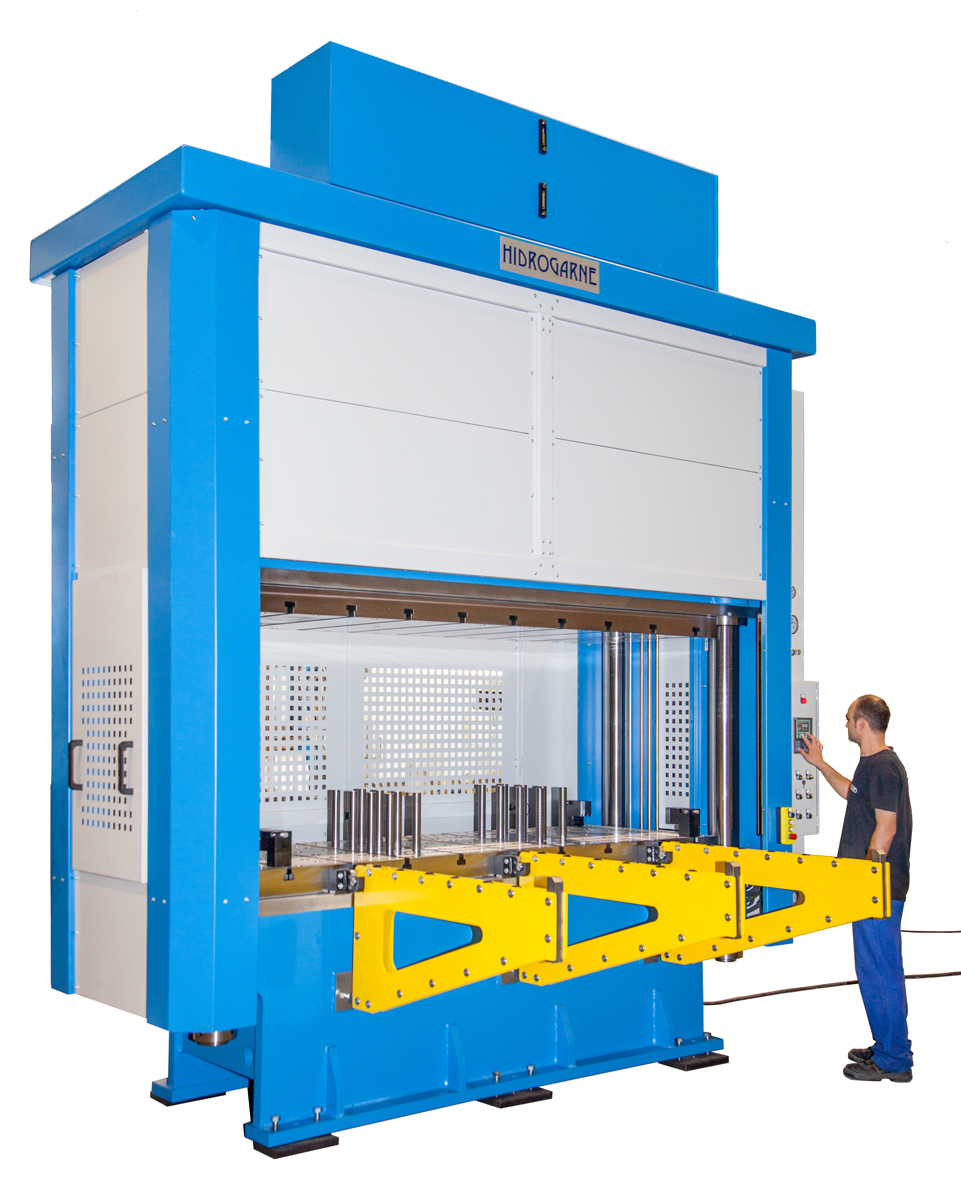

4- CYLINDRICAL COLUMN HYDRAULIC PRESSES

We present the M/NC SERIES of hydraulic presses, designed with four cylindrical columns to provide efficient and precise solutions in a wide range of industrial applications, especially recommended for stamping, deep drawing, blanking, and deburring.

This series, composed of six different powers ranging from 50 to 300 tons, represents excellence in performance and versatility.

They operate with a hydraulic pressure lower than 320 BAR to ensure greater durability of the entire hydraulic system.

STRUCTURE AND TABLES

The hydraulic presses of the M/NC series consist of three electro-welded structures made exclusively of S355JR steel. They are stabilized and machined at the end of the welding process to guarantee perfect parallelism and precision. Calculated and designed with finite element software. With all this, we always guarantee our high standards of precision and quality.

They are equipped with an upper table and a lower table made of C45E steel machined with DIN-650 grooves. We guarantee minimal friction in the vertical movement of the upper table by installing maintenance-free bimetallic bushings and perfect parallelism through four chrome-plated and ground cylindrical columns.

CYLINDER AND HYDRAULIC GROUP

Double-acting cylinder with seamless cold-drawn tube, chrome-plated piston, and maintenance-free wear-resistant guides.

Motorized hydraulic group with two speeds with automatic disconnection of the fast speed. It includes a cylinder decompression valve. Silent hydraulic pump.

ELECTRICAL INSTALLATION AND SAFETY

It incorporates a SIEMENS safety PLC model SIMATIC S7 1200 and a 4″ touchscreen model MTP-400 located at the top of the electrical drive pedal as standard. It allows programming the operating mode in semi-automatic and automatic, the power, the stroke, and the dwell time of the upper cylinder. It has a storage capacity of 99 recipes, and all the aforementioned values can be programmed in each recipe.

The electrical panel incorporates a selector that allows choosing the type of work we want to perform in manual or automatic position and a key selector for maintenance work. Electrical and hydraulic maneuvers are redundant and self-controlled. They incorporate an additional safety block and self-control devices for maneuvering and safety.

It includes the verification and certification of correct operation and the safety distance for photocells. To guarantee safety, they incorporate safety photoelectric barriers type 4 PLe, located in the frontal work area, two fixed side protections, and a practicable protection with a magnetic disconnection detector located in the rear part with polycarbonate windows and interior LED lighting.

They allow the installation of a hydraulic cushion or ejector. Complies and meets all essential safety and health requirements according to CE regulations. They come with an instruction manual.

TECHNICAL FEATURES

| MODEL | MV-50/NC | MV-80/NC | MV-100/NC | MV-150/NC | MV-220/NC | MV-300/NC | |

|---|---|---|---|---|---|---|---|

| Power | t | 50 | 80 | 100 | 150 | 220 | 300 |

| Motor power | kw | 5.5 | 7,5 | 13 | 13 | 11 | 11 |

| Piston stroke | mm | 450 | 450 | 450 | 450 | 450 | 450 |

| Approaching speed | mm/s | 45 | 34 | 40 | 28 | 17 | 13 |

| Working speed | mm/s | 9.9 | 8 | 3-9 | 3-7 | 3.8 | 2.8 |

| Return speed | mm/s | 60 | 48 | 62 | 40 | 30 | 18 |

| Guides diameter | mm | 60 | 80 | 100 | 120 | 120 | 150 |

| Useful table | mm | 750×620 | 900×850 | 1050×950 | 1050×950 | 1200×950 | 1300×1000 |

| Between columns | mm | 750×410 | 900×600 | 1050×650 | 1050×590 | 1200×590 | 1300×570 |

| Vertical light | mm | 600 | 600 | 650 | 700 | 750 | 800 |

| Working height | mm | 750 | 800 | 800 | 800 | 900 | 900 |

| Total front | mm | 1470 | 1680 | 1880 | 1940 | 2240 | 2650 |

| Total lateral | mm | 1020 | 1330 | 1430 | 1490 | 1460 | 1500 |

| Total height | mm | 2650 | 2680 | 2780 | 2885 | 3125 | 3250 |

| Weight | kg | 3200 | 3400 | 4300 | 5580 | 8500 | 10800 |

OPTIONAL ACCESSORIES

- Proportional pressure and flow valves.

- Adjustable hand panel with 7” touch screen mod. MTP700.

- Removable lower table.

- Hydraulic cushion.

- Hydraulic ejector located on the upper table, lower table, or both.

- Robotic integration.

- Hydraulic group cooling equipment.

- Approaching speed up to a maximum of 200 mm/s through filling valves and lateral cylinders.

- Hydraulic connections for peripheral systems.

- Control panel with articulated arm

- Industry 4.0

- Router for remote access

- Geometry adapted to your needs.