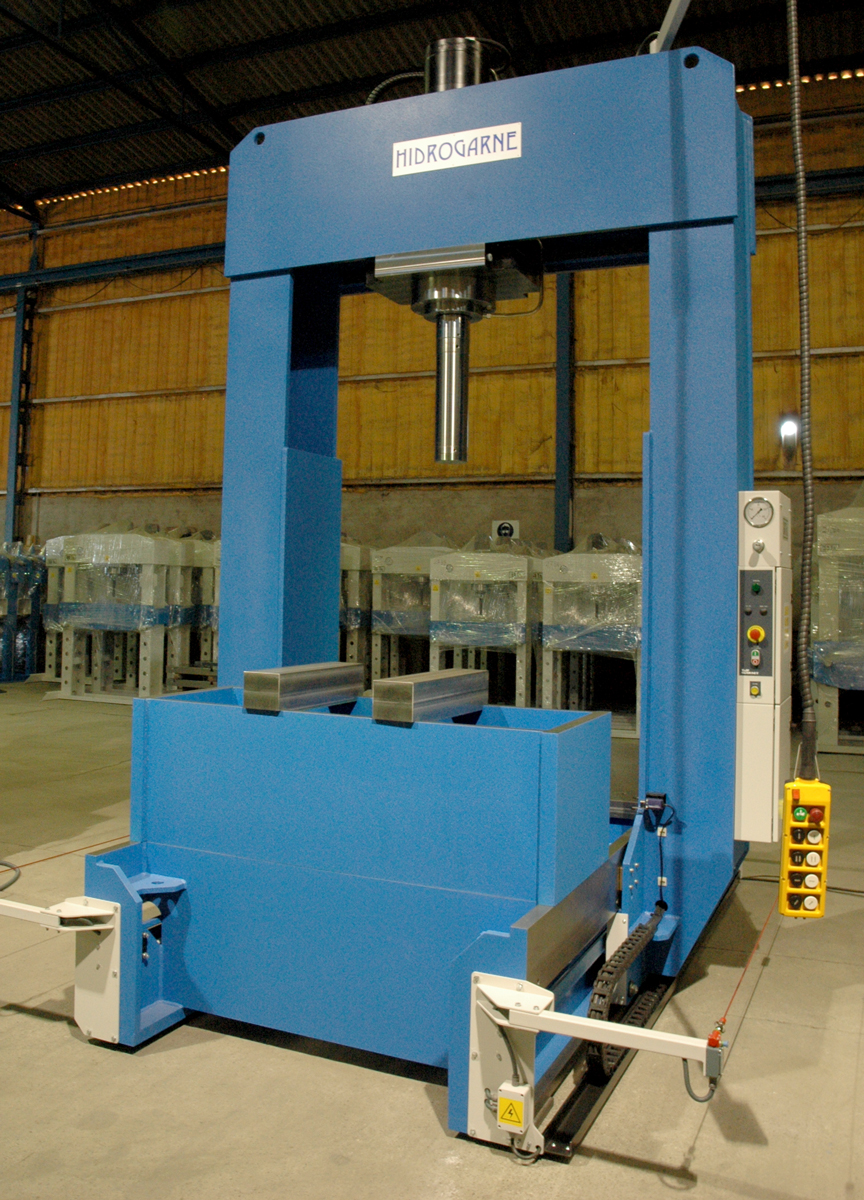

The TL-150E hydraulic press belongs to the T/NC series and is custom-designed and optimized for the stacking of rotors and stators.

As with all our hydraulic presses in the T/NC series, its design facilitates the loading and unloading of large pieces, plates, or structures. It allows access to different pressing points without the need to move the piece, thanks to the lateral movement of the cylinder and the longitudinal movement of the bridge.

It uses an optimized hydraulic system with a pressure of 305 Bar, ensuring prolonged durability and reliability in its performance.

Key adaptations include:

- Supplementary lower table of 1550 x 1550 mm with central hole for passing rotor shafts.

- Supplementary lower table with special configuration.

- Piston stroke: 1000 mm.

- Maximum vertical clearance between the piston and the lower table: 2000 mm.

It meets and satisfies all essential safety and health requirements according to CE regulations.

MORE INFORMATION

STRUCTURE AND TABLES

- Features an electrowelded structure made exclusively from S355JR steel.

- Stabilized and machined at the end of the welding process to ensure perfect parallelism and precision.

- Calculated and designed with finite element software.

- Longitudinal bridge movement is achieved using a frequency inverter and toothed belt.

- Lateral movement of the head is motorized.

- Supplementary lower table of 1550 x 1550 mm with central hole for passing rotor shafts.

- Supplementary lower table with special configuration.

CYLINDER AND HYDRAULIC GROUP

- Double-acting cylinder with lapped sleeve, chrome-plated piston, and maintenance-free anti-wear guides.

- Equipped with a removable and interchangeable pad to prevent wear on the piston and machined at the end to adapt to tooling.

- Includes a standard anti-rotation device for the cylinder and a calibrated front with end-of-stroke switches to adjust the cylinder’s travel.

- Motorized hydraulic group with two speeds and automatic disconnection of the rapid speed.

- Cylinder decompression valve.

- Pressure regulator.

- Glycerin manometer with tonnage reading.

ELECTRICAL INSTALLATION AND SAFETY

- The electrical panel includes a selector for choosing between manual or semi-automatic operation.

- Operation is carried out via a pendant control station with an emergency stop and low voltage control.

- Includes a maneuver confirmation button.