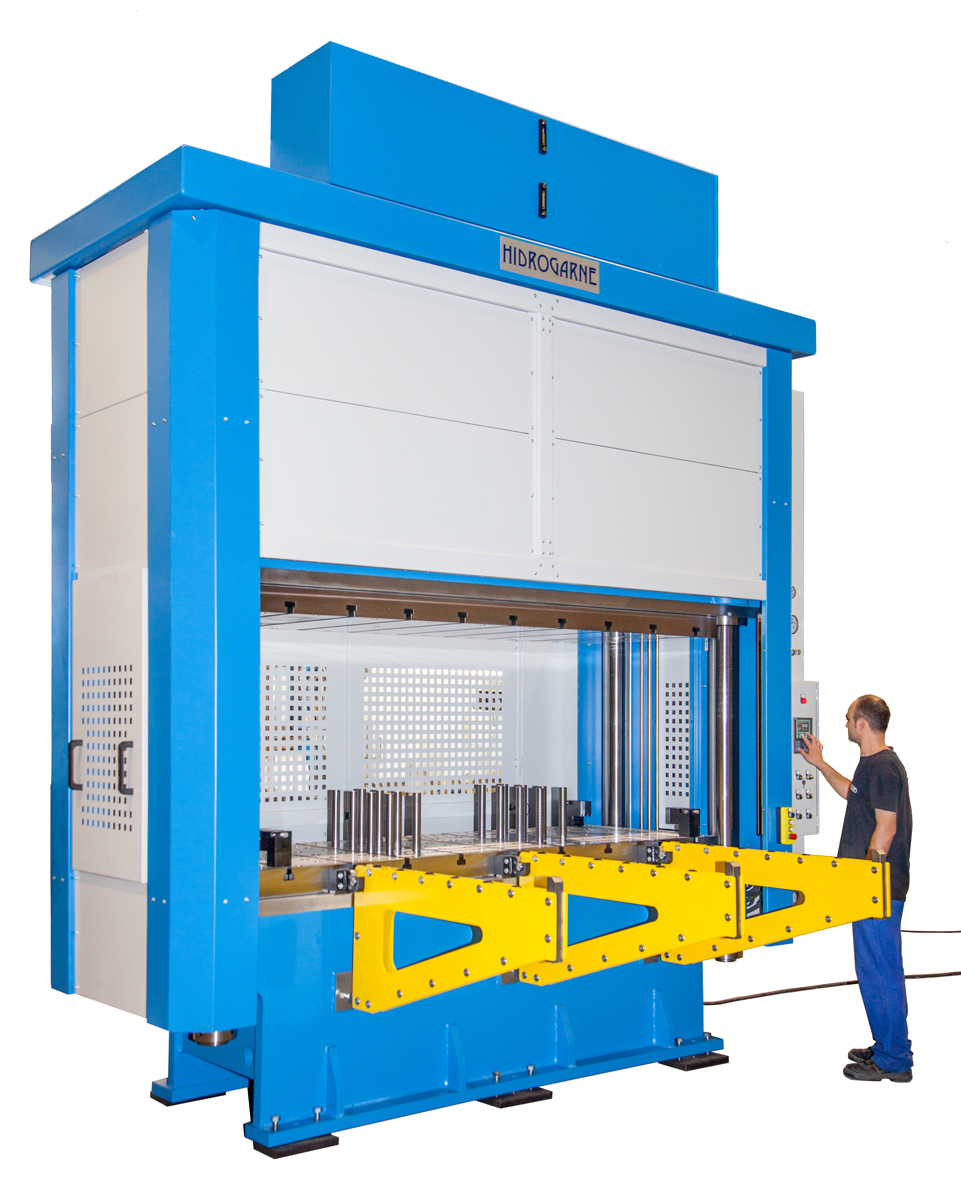

The MV-250E/NC four-column hydraulic press belongs to the M/NC series and is custom-designed for greater precision and capacity, specifically for deep drawing operations.

Equipped with a top and bottom table made of C45E steel, machined with DIN-650 slots to ensure minimal friction in the vertical movement of the top table, facilitated by maintenance-free bimetallic bushings and perfect parallelism achieved through four chromed and ground cylindrical columns.

It uses an optimized hydraulic system with a pressure below 290 Bar, ensuring prolonged durability and reliability in its performance.

It meets and satisfies all essential safety and health requirements according to CE regulations.

MORE INFORMATION

STRUCTURE AND TABLES

- Consists of three electrowelded blocks made exclusively of S355JR steel.

- Stabilized and machined at the end of the welding process to ensure perfect parallelism and precision.

- Calculated and designed using finite element software.

- The bottom table has a 50 Tn hydraulic cushion with a useful surface of 950 x 750 mm and three front consoles to support the die outside the press.

- Incorporates a SIEMENS KTP-400 NC for the regulation of the top table stroke, speed changes, and cushion regulation.

- Includes a SIEMENS S-7 PLC that allows programming of 99 memory settings.

CYLINDER AND HYDRAULIC GROUP

- Single-acting cylinder with lapped sleeve, chromed piston, and anti-wear guides.

- The entire hydraulic group is installed on the upper part of the press.

- The hydraulic group includes a silent hydraulic pump by Denison and an air-oil cooler.

- Includes:

- decompression system,

- pressure solenoid valves,

- pre-fill valves,

- communication valve,

- check valve,

- pressure relief valve, and

- anti-fall valve.

ELECTRICAL INSTALLATION AND SAFETY

- Incorporates a SIEMENS SIMATIC S7 1200 safety PLC and a 4” KTP-400 touch screen located on the electrical panel. Allows programming of semi-automatic and automatic modes, power, stroke, and dwell time. It has a storage capacity of 99 recipes, each recipe can program all the above values.

- The electrical panel includes a selector that allows choosing the type of work to be performed in manual „Adjustments” or automatic cycle „Production”.

- The machine operation is via low voltage electric pedals.

- For safety, it includes level IV photoelectric barriers located in the front working area, two fixed side guards, and a practicable guard with a magnetic disconnection detector located at the rear.

TECHNICAL SPECIFICATIONS

| MODEL | MV-250E/NC | |

| Power | tn | 250 |

| Motor power | hp | 20 |

| Piston stroke | mm | 500 |

| Approach speed | mm/s | 80 |

| Working speed | mm/s | 7 |

| Return speed | mm/s | 105 |

| Guide diameter | mm | 150 |

| Maximum pressure | Bar | 260 |

| Useful table area | mm | 2.500 x 1.150 |

| Between columns | mm | 2.500 x 700 |

| Maximum vertical clearance | mm | 1.000 |

| Minimum vertical clearance | mm | 500 |

| Cushion distribution area | mm | 950 x 750 |

| Working height | mm | 1.100 |

| Total height | mm | 3.650 |

| Weight | kg | 15.000 |